Manufacture of Soda Ash By Solvay-Ammonia-Soda Process

Introduction

Sodium Carbonate (Na2CO3)

commonly called Soda Ash or Sal Soda and hydrated sodium carbonate (Na2CO3.10H2O)

generally called washing soda are commercially manufactured by Solvay’s Process or Ammonia-Soda Process which was developed in 1861 by Belgian scientist, Ernest Solvay. Sodium bicarbonate (NaHCO3)

commonly known as baking soda or cooking soda is a valuable intermediate product of Solvay’s process.

Merits of Advantages of Solvay’s Process

Solvay’s

process has following advantages:

1. It gives soda of much higher purity (99.5).

2. It is a low cost process as raw materials are very cheap and less expensive.

3.Neither wastage of materials occurs nor harmful by-products forms.

4.No pollution problems as no gaseous pollutants are formed.

5.it

is a highly

efficient process as about 97%

CO2 is used up in this process.

6.Sodium bicarbonate is obtained as a valuable intermediate.

7.Calcium chloride (CaCl2) is a

useful by-product.

8. It is a cyclic, continuous and self-contained process as raw materials like NH3 and CO2 are recovered

and recycled.

Raw Materials and their Sources

Basic Principle

The process is based on the

formation of ammonium bicarbonate by the reaction of NH3, CO2 and water which on

double decomposition with sodium chloride solution gives precipitate of sparingly soluble salt of sodium bicarbonate which is ignited to give anhydrous sodium

carbonate.

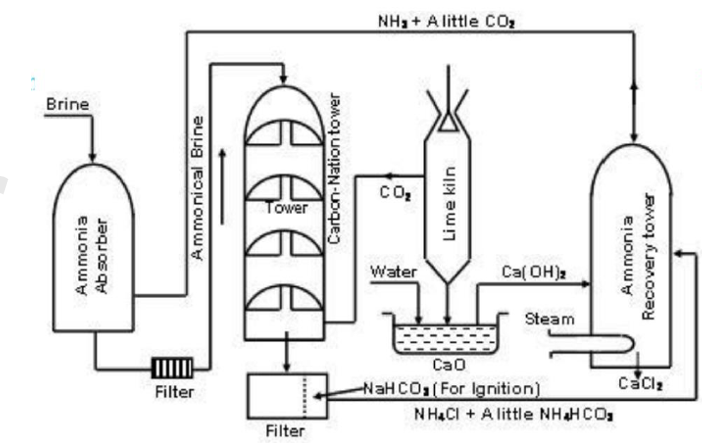

Different Steps of Process

1.Ammoniation of Brine in Ammoniating

Tower (Saturation of Brine with Ammonia).

2.Carbonation

of Ammoniated Brine in Carbonation Tower.

3.Filtration in rotary suction filter

(vacuum filtration chamber).

4.Calcination and decomposition of Sodium

Bicarbonate into soda ash and then its recrystallization

5. Ammonia

Recovery.

1.Ammoniation of Brine in

Ammoniating Tower (Saturation of Brine with Ammonia)

In the ammoniating tower (ammonia

absorber), a saturated solution of sodium chloride (about 28% by mass) called brine containing some

CO2 is thoroughly agitated with ammonia gas (coming from Ammonia Recovery Tower or

ammonia generator) until saturated ammoniated

brine is obtained.

[The tower consists of mushroom-shaped baffles at short intervals which control

the flow of brine ensuring proper saturation with ammonia passing up the

tower].

The ammonical brine so produced is allowed to stand for some time so that any impurities of

calcium, magnesium or iron salts present in brine are precipitated as carbonates and hydroxides settle down which are filtered off. The impurities settle down and clear

solution is passed through carbonating tower.

2. Carbonation of Ammoniated Brine

(a) Production of CO2

For carbonation of ammoniated

brine, CO2 is produced by heating lime stone to 1000°C in a furnace

called Lime

Kiln.

(b) Saturation of Ammonical

Brine with CO2

In Solvay or carbonation tower,

carbonation of ammonical brine is carried out on the Counter-current

process. Ammonical

brine is allowed to trickle down a carbonating (Solvay) tower (fitted with

baffle-plates) where it meets an upward current of carbon dioxide gas (coming

from a lime kiln produced by heating lime stone) introduced from the bottom of

the tower at a pressure of 1-2 atmosphere. [The baffle-plates check the flow of

ammonical brine and break up the CO2 into small bubbles to ensure

good conditions for the reaction].

Here CO2 and NH3

reacts with water to give NH4+ and HCO3–

ions which then react with Na+ and Cl– ions of brine to

precipitate less soluble sodium bicarbonate leaving ions of NH4+

and Cl– in solution. Since the overall effect of these reactions is

exothermic, the temperature of materials rises. This tends to increase the

solubility of NaHCO3 thereby inhibiting its precipitation. To

counter this adverse effect, the lower part of tower is cooled to 15°C.

3. Filtration in Rotary Suction

Filter

The intermediate product soda

bicarbonate is filtered in a vacuum filtration chamber where ammonium salts are

removed. (The thick milky suspension of NaHCO3 and NH4Cl

from the base of carbonating tower is them filtered (by means of rotary suction

filter where two products are separated). The precipitated soda bicarbonate

left on filter cloth is scrapped off after washing with a spray of cold water

and dried to free of ammonium salts. The filtrate or mother liquor containing

ammonium chloride is pumped to the ammonia recovery tower).

4. Calcination of Sodium Bicarbonate followed by recrystallization

The precipitate of NaHCO3

is ignited (in specially constructed cylindrical vessels) to give anhydrous Na2CO3

or soda ash. CO2 evolved is recycled to carbonating tower to use it

again. Washing soda (decahydrate Na2CO3.10H2O)

is produced from soda ash by re-crystallization from its hot aqueous solution.

5. Ammonia Recovery

In ammonia recovery tower, solution

of NH4Cl is made to react with quick lime; CaO (obtained from lime

kiln) or with slaked lime (obtained by reacting CaO and steam) to give NH3

which is recycled to saturation tank. CaCl2 is a by-product.

Summary

The

manufacturing of washing soda from brine involves its ammoniation in ammoniating

tower where brine is saturated with

ammonia and impurities are settled down followed by carbonation of ammoniated brine in Solvay (carbonation) tower where

brine reacts with ammonium bicarbonate to precipitate less soluble baking soda

which is thermally decomposed on calcination to yield soda ash which on

recrystallization from hot its hot aqueous solution gives washing soda.