Extraction

of Copper from Sulphide Ore

Ore used and Type of Metallurgy

Copper is extracted

mainly from sulphide ore, copper pyrite (Chalcopyrite), CuFeS2 (CuS

+ FeS or Cu2Fe2S4 i.e. Cu2S + Fe2S3)

which contain about 34% (6% in book) copper by Pyrometallurgy (Dry Process).

Main steps of Metallurgy

Extraction

of Copper from sulphide ore involves the following steps:

1. Crushing of Ores into Powdered Form

The big

blocks of ores are crushed into small pieces and then finally powdered.

2. Concentration of Crushed Ore

Ores are often

contaminated with non-metallic and rocky impurities like sand (quartz), clay,

mica, lime stone etc which are called gangue or matrix. The removal of unwanted

impurities from the ore before metallurgical process is called Concentration or benefication or ore

dressing. Copper pyrite is a low grade copper ore containing about 34%

copper along with impurities such as sand, clay, lime stone etc.

The

powdered ore is concentrated by froth

floatation process (Selective Wetting) which is based upon preferential wetting of surfaces by

liquids on account of the surface

tension forces.

The powdered or

crushed ore is concentrated by froth floatation process, in which the crushed

ore is mixed with a mixture of Pine Oil

or creosote oil and water and then thoroughly agitated with a blast of air.

The ore is miscible (get wetted) with oil forming froth and rises to the top from

where they are skimmed off and dried to get concentrated enriched ore whereas

the gangue particles (impurities) are wetted by water and settle at bottom.

Copper content is increased to 25-30% in this way.

3. Roasting

Roasting

is a process in which the concentrated ore is strongly heated in a current of

excess of air below the melting point of ore in the hearth of a large flat

Reverberatory Furnace. Roasting not only dries the ore but also bring about

following changes:

(i) Impurities like C, S, P, As,Sb in the ore are

removed as their volatile oxides. It also removes organic matter

|

S

|

+

|

O2

|

¾¾¾¾¾®

|

SO2

|

|

4Sb

|

+

|

3O2

|

¾¾¾¾¾®

|

2Sb2O3

|

|

4As

|

+

|

3O2

|

¾¾¾¾¾®

|

2As2O3

|

(ii)Copper

pyrite (ore) is converted into a mixture of Cuprous Sulphide and Ferrous Oxide.

Some FeS present in the ore remains unreacted. At the end of roasting, the ore

has been now contained Cu2S, FeO and FeS.

4. Smelting (Formation of Molten Matte)

Smelting

is the process of reduction of oxide of ore by reducing agent (like coke) under

such conditions that metal is obtained in molten state.(In copper extraction,

smelting serves to remove gangue).

A charge

consisting of Roasted Ore, powdered Coke (reducing agent) and sand (flux) is strongly

heated in a Water Jacketed Blast Furnace and a blast of hot air is blown at the

lower part of furnace through tuyeres. During smelting coke burns releasing heat

of combustion which serves to keep the charge in molten state.

The

Ferrous oxide present in ore combines with sand (flux) to form fusible ferrous

silicate (slag) which being lighter rises to the top and is withdrawn from the

upper hole.

The

molten mixture of Cu2S and FeS is left behind after smelting which

is called Molten Matte or Course Metal wchih contains about 45% copper. It

being heavier, forms the lower layer and is withdrawn from the lower hole

periodically.

5.

Bessemerisation (Formation of Blister Copper)

The reduction

of molten matte is carried out in a pear-shaped stainless steel furnace called

Bessemer converter which is lined inside with MgO also provided with tuyers.

The

molten matte is heated in Bessemer converter by blowing hot blast of air

through pipes called Tuyers with more silica. The following changes occur in

the converter:

(i) Air oxidizes most of FeS to FeO by direct

oxidation which is removed as ferrous silicate (slag) by combining with silica.

FeS is also converted into FeO by reacting with Cu2O (formed by

partial oxidation of Cu2S).

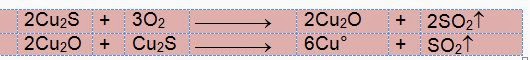

(ii) After

the iron has been removed, hot blast of air partially oxidizes Cu2S

into Cu2O (leaving some unreacted Cu2S). Now Cu2O

and remaining Cu2S reduce each other (Auto or self reduction)

without any external reducing agent to give metallic copper in molten state.

Blistered Copper

The molten metal produced is now cooled to solidify in

sand moulds, the dissolved and hidden SO2 gas escapes out, produces

blisters (bubbles) on the surface of solid metal, so copper obtained is called

BLISTERED COPPER which is 98-99% pure.

Since the reaction is exothermic, the heat liberated

keeps the crude copper in the molten state. The completion of the reaction is

indicated by the appearance of green flame produced by the vapourization of

copper.

6. Electrolytic Refining of Blistered Copper

Blistered copper

contains impurities mainly Ag, Au, Pt, Ni, Zn, Fe, As, Pb, As etc. Hence for

electrical purposes, blister copper obtained after bessemerization is refined

electrolytically to get copper of high purity (99.95-99.99).

The

refining of Blistered Copper is carried out in a large Lead-Lined Tank using a

series of anode of thick impure blister copper which places alternately with a

series of cathodes of thin plates of 100% pure copper (The cathodes are coated

with graphite so that the deposited pure copper may be removed easily). These

electrodes are suspended in an electrolytic solution of CuSO4 (15%) acidified

with traces of dilute H2SO4 (5%).

On

electrolysis, the atoms of anode (impure copper metal and other active metals

such as Fe, Zn, Bi etc) are oxidized to their corresponding cations and pass

into solution. The impurities of less active metals such as Ag, Au etc are not

oxidized and settle down just below the anode as anode mud. The current

of 1.3–1.5 volt is used for electrolysis which helps to deposit only copper on

cathode leaving behind other metal ions in solution. The electrolytically

refined copper is 100% (99.99%) pure. With the deposition of copper, cathode

grows thick and anode becomes thin due to dissolution of the metal.

Electrolytic Reactions

Nice

ReplyDeleteThanx Shaks. Keep visiting my blog.

Deleteits very helpful for me

ReplyDeleteThanks .. nice information !

ReplyDelete